Acquiring new laboratory fume cupboards for the first time can be incredibly daunting for beginners. With so many different variables to acknowledge, understanding where to begin can be more trouble than it's worth. To address this, we're exploring the top five features that every fume cupboard enthusiast should consider:

Your first decision is whether to go ducted or ductless. A ductless fume cupboard sucks air into the front of the unit through a filter (or filters) and then exhausts air back into the room. This makes ductless fume cupboards an excellent choice for applications that do not require large quantities of chemicals and where movability is a prime consideration.

The cost of installing and commissioning a ductless fume cupboard is also significantly lower, but this does come with some unfortunate caveats. These include the ongoing cost of replacement filters and the prohibited use of certain chemical compounds.

However, as environmental controls increase, more and more people are choosing recirculating (ductless) units as exhausting dangerous chemicals back into the atmosphere is something local authorities are striving to avoid.

On the other hand, Ducted fume cupboards follow this very principle. They focus on extracting air through the front of the unit and releasing fumes back into the atmosphere through custom-built ventilation systems. The benefit of using a ducted solution is that once fitted, there is very little to no maintenance work required aside from the 14-month LEV test. Often, ducted fume cupboards are an ideal solution when labs are undergoing essential maintenance or construction work, allowing installers to assemble and fit the ventilation shafts without creating any ongoing disruption. Moreover, ducted units can handle large chemical quantities with no filter limitations, significantly increasing their versatility.

Our expert opinion: “If you have an existing lab go ductless. This is simply because the reduced installation cost will more than offset the ongoing investment in filter replacements. If you plan on building a new lab (or have simple access to run ducting), go ducted. It allows for more varied usage and the ongoing cost is minimal.”

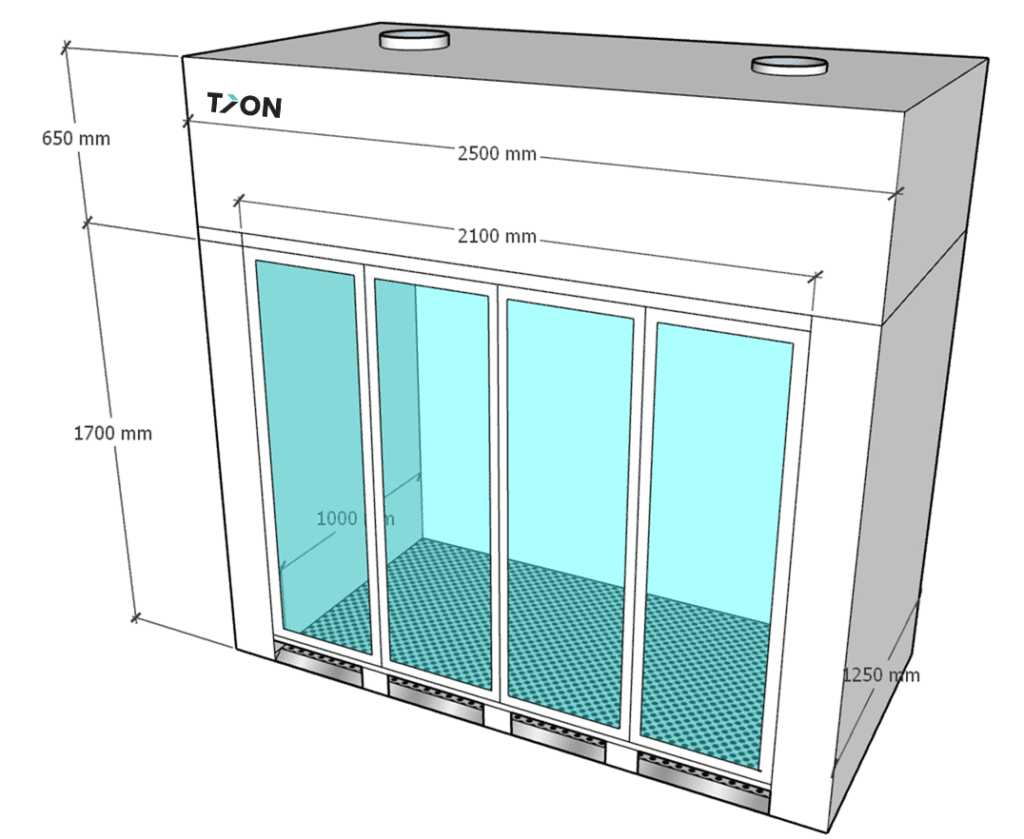

Do you have the necessary access requirements and space to accommodate a new fume cupboard? Doorway widths, corridors and ceiling heights should be clearly defined and considered in the planning phase. Otherwise, you could incur unexpected costs for specialist equipment.

Our expert opinion: “If you don’t know you’ve captured all the information you need…. ask! The manufacturer should be able to help you with anything you may have missed!"

What size fume cupboard is perfect for you? Just because manufacturers only advertise one standard size unit, other options could still be available. Specify exactly what you need in terms of dimensions and specifications to ensure you get the best result.

Maybe you require a specialist piece of equipment, such as a workbench or storage cabinet? Well, pass this information on to your manufacturer. They can custom-build a bespoke unit that optimises your space and suits your needs.

Our expert opinion: “Write down your perfect specification before looking at what’s available on the market. Fume cupboard specialists should rarely have a problem with designing to your spec. You can always scale back from there if what you are looking for is physically not possible. It’s always worth asking the question!”

Is there a specific set of chemicals you intend on using inside your cabinet? Knowing your requirements to avoid adverse effects or chemical reactions with standard spec materials is paramount. For example, fume cupboard sashes traditionally use toughened glass. However, for those using hydrofluoric acid, this will etch the glass badly. The solution here could be a polycarbonate sash.

Our expert opinion: “Share your list of chemicals and usage quantities with the manufacturer early on in the planning process to make sure you get the best recommendations possible. They are likely to have a solution for your requirement”.

Fume cupboards (particularly ducted) require vast amounts of energy to function, which causes significant heat loss due to the sheer volume of air extracted from the room. When installing a cupboard, the face velocity should be set between 0.3 and 0.5m/s with the sash at working height. Ultimately, this means that the face velocity will change depending on the height of the sash. As the face velocity drops, user safety becomes a risk. Likewise, when the face velocity increases, energy loss occurs.

The solution is VAV or variable air volume functionality, which controls the face velocity based on the height of the sash. This not only ensures the safety of the operator at all times but also drastically reduces heat loss. In addition, the fan speed is reduced when the sash is lowered, increasing the product's life expectancy.

In a busy lab, VAV can pay dividends and, over time, can show significant savings in heating and energy. Read more about VAV here.

Our expert opinion: “Where possible, budget for VAV. You will cover your initial costs within the first two years of operating your fume cupboard.

To find out more about choosing the right fume cupboard for your space, contact our team today.

You can also download our free "Five Things To Consider When Choosing Fume Cupboards" infographic: