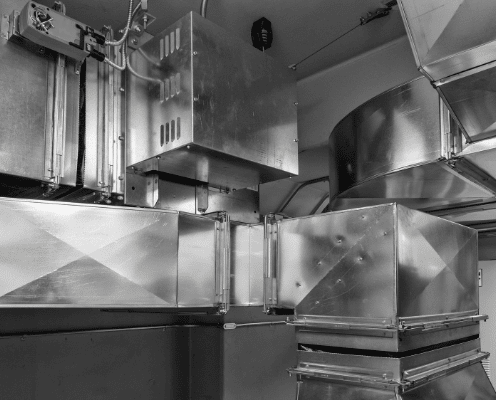

Fume cupboards are a crucial tool in laboratories, protecting users from toxic substances (fumes, dust etc.). A typical laboratory fume cupboard pulls air from inside the room through the open sash, taking hazardous and noxious gas particles with it. The contaminated air is then vented externally or passed through filters and recirculated back into the room.

The average chemical fume hood exhausts approx. 20-30 m³/min of conditioned air. This places a significant load on the HVAC system and operational costs. However, converting from a CAV (Constant Air Volume) solution to a VAV (Variable Air Volume) system can reduce this load considerably.

CAV provides a constant flow of air, regardless of whether or not the fume cupboard is in use (with the sash open or closed). As a result, the machine wastes a substantial amount of energy.

Closing the sash on a CAV hood will also increase the face velocity (or "pull" at the front of the fume cupboard). Consequently, this disturbs the equipment, slows experiments, and could push contaminated air back into the room.

On the other hand, RAV (Reduced Air Volume) is a limited and (in our opinion) flawed half-hearted attempt to reduce energy usage and costs. The system is calibrated to a lower face velocity (commonly 0.4 m/s instead of 0.5 or 0.6m/s). Although, this increases the risk of exposing users to fumes and only reduces exhausted air by 20%.

In contrast, a VAV system reduces the volume of air taken from the fume cupboard when the product is not in use and the sash is closed. This type of system, which can be fitted as part of a new installation or retrofitted to any existing laboratory, has several significant benefits as follows:

A Variable Air Volume system allows the fume cupboard to operate at minimum exhaust volumes when the sash is closed. Creating a highly responsive energy usage system that's tailored to the user's needs. The exact saving depends on user behaviour, but in general, the less the hoods are open (in terms of height and time), the greater the energy savings.

Example:

With many educational and commercial laboratories under pressure to meet carbon emission targets, VAV airflow controllers reduce energy wastage, ensuring a reduction in carbon emissions.

Variable Air Volume systems may increase the initial costs, but customers fitting VAV controllers can reduce energy expenditure by up to 90%. Allowing businesses to achieve a quick ROI.

Reading University recently upgraded 44 sizable fume cupboards from CAV to VAV. The results speak for themselves, achieving annual energy savings worth £223,958. Essentially, the system paid for itself in less than four years.

The higher the number of fume cupboards in each room/area, the greater the potential savings. This is because fume cupboards are significant contributors to the achievement of required overall air exchange rates.

The above example of a 1500mm CAV cabinet equates to the following saving:

That amounts to an annual saving of £1,100.56 for one cupboard!

On top of this, there is the real issue of sashes NOT being closed at night. We estimate the real-life cost saving of a 1500mm cupboard with an auto sash to be even higher than the above.

Universities often have much larger (2000mm+) units, and the above real-life example saved £5090.00 per unit, per year.

VAV systems ensure a constant face velocity regardless of sash position, safeguarding the users from potentially hazardous fumes. It's a great way of guaranteeing your staff peace of mind and maintaining compliance with the latest health and safety regulations.

The on/off cycling of CAV or RAV systems causes laboratory temperatures to vary whilst a VAV system keeps it constant. This results in more precise space temperature control. In addition, because the air is exposed to cooling coils for a longer time in a VAV system, the air is passively dehumidified too, creating a more comfortable environment for users.

TION's VAV Controller with integrated Auto Sash will adjust the airflow according to your needs, decreasing the volume of extract when fume cupboards are not in use and can reduce energy consumption by up to 90%. Featuring a full-colour, intuitive interface that’s easy to navigate, it facilitates simple calibration and offers full alarm diagnostics and test functionality.

Need to test the velocity of your fume hood? Check out our guide for everything you need to know. Still have questions? Contact our team today.